You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Ported Saws... Lets see your work fellas

- Thread starter BigSachsDolmar

- Start date

Moparmyway

Member

Ported 3120 with a 36" 8 tooth 404

The 026 was kicking. It was really interesting to me. I'm about to port one.Just uploading today's video fully burried 32 inch bar on the 038, share it when it's done

Ported 038 mag with 8 pin rim, 24 inch bar

Ported 026 This one will either make you laugh, shake your head or surprise you... had lots of nay sayers and haters until seeing this video, and i can't seem to say this enough it is not its full time life with this bar and was for entertainment purposes only

Same ported 038 as above 038 with a 32 inch full comp

Iroczu

Member

It was that 32 was purely forThe 026 was kicking. It was really interesting to me. I'm about to port one.

Entertainment purposes with low expectations it would have pulled it, and do not recommend it for a few reasons which all lead to failures from engine or clutch or both lack of oil for the bar also. I ran a 18 with 325 on it last night in 20 inch wet cotton wood just cut last weekend since i was testing buddies 028 after a muffler mod figure bar uo the 026 and compare nearly stock vs ported and that was a riot

I'll probably run a 20" on mine for a limbing saw.It was that 32 was purely for

Entertainment purposes with low expectations it would have pulled it, and do not recommend it for a few reasons which all lead to failures from engine or clutch or both lack of oil for the bar also. I ran a 18 with 325 on it last night in 20 inch wet cotton wood just cut last weekend since i was testing buddies 028 after a muffler mod figure bar uo the 026 and compare nearly stock vs ported and that was a riot

I bought the saw new in 1985 I think. The piston looks wonderful through the exhaust port.

So we shall see.

Mastermind

Active member

I'll have to admit you got my rusty gears to turning.

I'm new to porting, but not shy to push the limits.

Mastermind

Active member

I'll have to admit you got my rusty gears to turning.

I'm new to porting, but not shy to push the limits.

One of the reasons I don't post a lot of this stuff is because I hate the thoughts of leading people down a rabbit hole. These type of ports are absolutely not needed on 95% of the engines you will port. In fact, on most engines they may even be detrimental to performance. This 3120XP is a 60mm bore......and these finger ports are huge. They open a wee bit ahead of the main transfer ports in order to help push the spent exhaust out. They work pretty well on a large bore engine......but I wouldn't bother with them on a smaller engine.

Mastermind

Active member

Nutball

Active member

Farmertec kit, MMWS Cross cylinder, I think Moparmyway did the machine work on the cylinder, I tweaked the ports a little. 32" bar

View attachment Chinese 660 short.mp4

View attachment Chinese 660 short.mp4

Mastermind

Active member

Farmertec kit, MMWS Cross cylinder, I think Moparmyway did the machine work on the cylinder, I tweaked the ports a little. 32" bar

View attachment 564

Holds great rpm

Understood.One of the reasons I don't post a lot of this stuff is because I hate the thoughts of leading people down a rabbit hole. These type of ports are absolutely not needed on 95% of the engines you will port. In fact, on most engines they may even be detrimental to performance. This 3120XP is a 60mm bore......and these finger ports are huge. They open a wee bit ahead of the main transfer ports in order to help push the spent exhaust out. They work pretty well on a large bore engine......but I wouldn't bother with them on a smaller engine.

For now I'm pretty much sticking to the basics, but as I get better I will push them to see where it will go. It's only a chainsaw.

Nutball

Active member

Holds great rpm

That's probably my doing, I like to run them smooth where they feel like they cut best or fastest. The guys at the removal company I work at repetitively lean on them until they almost stall, let off, and repeat.

Just for fun experimenting with this farmertec kit ms250, and also to see how well JB weld holds up in a cylinder. I tried reducing the volume in the crank case by stuffing it with JB weld. Also added JB to the intake, and upper transfers to perhaps help the mix flow around the otherwise sharp corners, similar angle to what the Echo 490 & 590 have. I'm not sure if it helped, but the saw runs well. It definitely needs a lower exhaust port and higher compression.

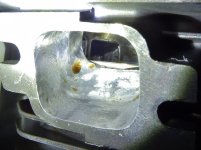

Below, one side of the lowers setup, about to fill the other, but before smoothing and clearancing for the piston.

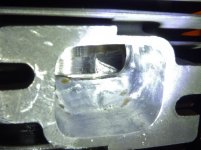

No time spent purtying up the exhaust port, just hogged it out a lot.

In the video I was testing the stock muffler on it because the one I modified to exit out the front felt like it may have lost some low end torque, but gained a little high end torque. Even though the ms250 seems to have a lot of cooling surface area compared to other saw engines, it starts out quite sporty when cool, but after 5min or so of non stop firewood cutting, it seems to slow down a lot.

First cuts, not broken in yet, still tuning during that session. I attribute the low end torque to the raised and widened intake. I might leave the intake lower on my second kit. Cedar, then Hickory.

View attachment Kit 250 Stock Muff.mp4

Mastermind

Active member

That little bugger is getting it.That's probably my doing, I like to run them smooth where they feel like they cut best or fastest. The guys at the removal company I work at repetitively lean on them until they almost stall, let off, and repeat.

Just for fun experimenting with this farmertec kit ms250, and also to see how well JB weld holds up in a cylinder. I tried reducing the volume in the crank case by stuffing it with JB weld. Also added JB to the intake, and upper transfers to perhaps help the mix flow around the otherwise sharp corners, similar angle to what the Echo 490 & 590 have. I'm not sure if it helped, but the saw runs well. It definitely needs a lower exhaust port and higher compression.

Below, one side of the lowers setup, about to fill the other, but before smoothing and clearancing for the piston.

View attachment 565

No time spent purtying up the exhaust port, just hogged it out a lot.

View attachment 567

View attachment 568

In the video I was testing the stock muffler on it because the one I modified to exit out the front felt like it may have lost some low end torque, but gained a little high end torque. Even though the ms250 seems to have a lot of cooling surface area compared to other saw engines, it starts out quite sporty when cool, but after 5min or so of non stop firewood cutting, it seems to slow down a lot.

First cuts, not broken in yet, still tuning during that session. I attribute the low end torque to the raised and widened intake. I might leave the intake lower on my second kit. Cedar, then Hickory.

View attachment 566

Iroczu

Member

100% for their cc class have good potential. That 18 and 325 it was Rowdy as heck. Good little sawsI'll probably run a 20" on mine for a limbing saw.

I bought the saw new in 1985 I think. The piston looks wonderful through the exhaust port.

So we shall see.

Iroczu

Member

I would be worried about how it fairs against the heatThat's probably my doing, I like to run them smooth where they feel like they cut best or fastest. The guys at the removal company I work at repetitively lean on them until they almost stall, let off, and repeat.

Just for fun experimenting with this farmertec kit ms250, and also to see how well JB weld holds up in a cylinder. I tried reducing the volume in the crank case by stuffing it with JB weld. Also added JB to the intake, and upper transfers to perhaps help the mix flow around the otherwise sharp corners, similar angle to what the Echo 490 & 590 have. I'm not sure if it helped, but the saw runs well. It definitely needs a lower exhaust port and higher compression.

Below, one side of the lowers setup, about to fill the other, but before smoothing and clearancing for the piston.

View attachment 565

No time spent purtying up the exhaust port, just hogged it out a lot.

View attachment 567

View attachment 568

In the video I was testing the stock muffler on it because the one I modified to exit out the front felt like it may have lost some low end torque, but gained a little high end torque. Even though the ms250 seems to have a lot of cooling surface area compared to other saw engines, it starts out quite sporty when cool, but after 5min or so of non stop firewood cutting, it seems to slow down a lot.

First cuts, not broken in yet, still tuning during that session. I attribute the low end torque to the raised and widened intake. I might leave the intake lower on my second kit. Cedar, then Hickory.

View attachment 566

Iroczu

Member

Only a rabbit hole if one wants to learn but never tries and only can learn from mistakes made.One of the reasons I don't post a lot of this stuff is because I hate the thoughts of leading people down a rabbit hole. These type of ports are absolutely not needed on 95% of the engines you will port. In fact, on most engines they may even be detrimental to performance. This 3120XP is a 60mm bore......and these finger ports are huge. They open a wee bit ahead of the main transfer ports in order to help push the spent exhaust out. They work pretty well on a large bore engine......but I wouldn't bother with them on a smaller engine.

Mastermind

Active member

Only a rabbit hole if one wants to learn but never tries and only can learn from mistakes made.

When I had a few hundred saws under my belt, I thought I had a lot of this stuff figured out. I would do a lot of build threads, and post a lot of videos. I shared my knowledge freely. I wouldn't necessarily say the information I was sharing was all wrong, but it wasn't all as accurate as it could have been either. The thing was that as I learned more, I realized that some of the stuff I thought I knew wasn't as true as I thought it was. In other words, the more I learned, the less sure I was about sharing. The problem is, there are so many different types of saw engine, that there is no certain recipe that applies to them all. For instance, the Husqvarna 5 series is a strato engine with really long transfer tunnels. It uses a very short blowdown time. The Stihl 201, 261, and 362 are also stratified but have short tunnels, and use a longer blowdown time. Rather than just grab a set of numbers from someone else's build thread, we should all be trying to figure out why these engine designers used the timing numbers that they did. Another example, using non-stratifed engines: The Dolmar 7900. Really tight transfer tunnels, and pretty small ports for an 80cc saw. This saw is designed with a long blowdown time. About 26° or so. The 7900 is a quad port design. The Stihl 046 has a two port design, wide open transfer area, and employs a very short blowdown time of about 14 - 16 degrees. I encourage everyone to study these different designs and try to figure out why they use such widely varied port timing numbers rather than playing follow the leader on their builds.

Nutball

Active member

Me too. I've pushed this saw hard for around 15 tanks, and the JB weld has turned dark brown from the heat, but still remains. It is rated for 550degF. I don't know how hot the inner walls of the engine get, but 400-450deg F is the hottest I've seen on any chainsaw cylinder so far. Usually they don't quite hit 400F. Another concern of mine is heat expansion cycles causing it to peel away from the cylinder, but in most cases I try to prep the surface in such a way that the epoxy is shaped so it can't easily fall out even if it completely detached from the aluminum.I would be worried about how it fairs against the heat

Buxton_Work_Saws

Member

Some of my work. Nothing I do is very extreme. I build working saws not race winners.

Port Work 395

395 cutting

Port Work 461

461 Cutting

Sent from my Pixel 4a using Tapatalk

Port Work 395

395 cutting

Port Work 461

461 Cutting

Sent from my Pixel 4a using Tapatalk