You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Ported Saws... Lets see your work fellas

- Thread starter BigSachsDolmar

- Start date

Yea, it is to lean. I'm not leaving this cylinder on it so I figured I keep leaning it until I got to the fastest it would cut, I didn't really care if I messed the cylinder up. I probale cut to much out of the band, I had it on and off the lathe so many time and lost track of how much I cut, I know I had to cut .080 off the base to get the squish to .019. It has a lot of compression and maybe that is causing a lot of heat. I'll go out and make a short cut with it and see if it still does it, that way it doesn't have time to get to hot.Sounds too lean. I'd imagine that is making it too hot and causing the running on. Personally, I like em fat. LOL

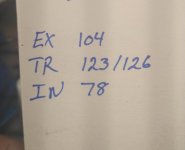

It might, I'm going it check in a bit.I'm betting there's an air leak what was your transfer blow down and duration on intake

Here's the numbers I used.

Attachments

Mastermind

Active member

Yea, it is to lean. I'm not leaving this cylinder on it so I figured I keep leaning it until I got to the fastest it would cut, I didn't really care if I messed the cylinder up. I probale cut to much out of the band, I had it on and off the lathe so many time and lost track of how much I cut, I know I had to cut .080 off the base to get the squish to .019. It has a lot of compression and maybe that is causing a lot of heat. I'll go out and make a short cut with it and see if it still does it, that way it doesn't have time to get to hot.

Too much compression will make one get leaner and leaner the longer it runs. I'm interested in your test results.

Buxton_Work_Saws

Member

Them numbers look perfect for a 361.. I'd say it's too lean .. like said above or you have a aftermarket carb issue. Some of them aftermarket carbs are real bad.. I've had them do simulator or you tighten the dang jets up tight and they are still fat... I'd say it's pretty safe to say it's not porting it's a tuning or carb issue.It might, I'm going it check in a bit.

Here's the numbers I used.

Sent from my Pixel 4a using Tapatalk

I'll post what I find this after noon. Right now I need some sleep, been up since 5am yesterday.Too much compression will make one get leaner and leaner the longer it runs. I'm interested in your test results.

So I before starting it I turned the H around 1/16 of a turn richer, started it and then turned the camera on. It must be getting to hot when I've got it on the edge, it's faster like that but that won't do me any good if it ends up scoring the cylinder. I don't know if the aftermarket carb comes into play here or not. When I checked the RPMs it was at 13,950. After making them cuts I pulled the back cover and sprayed the back of the cab with brake cleaner and didn't have a leak so that eliminates that. When the OEM carb gets here I'll put it on and see what happens.Too much compression will make one get leaner and leaner the longer it runs. I'm interested in your test results.

Drop the vid of the 2511 with 20" bar lol.That's probably my doing, I like to run them smooth where they feel like they cut best or fastest. The guys at the removal company I work at repetitively lean on them until they almost stall, let off, and repeat.

Just for fun experimenting with this farmertec kit ms250, and also to see how well JB weld holds up in a cylinder. I tried reducing the volume in the crank case by stuffing it with JB weld. Also added JB to the intake, and upper transfers to perhaps help the mix flow around the otherwise sharp corners, similar angle to what the Echo 490 & 590 have. I'm not sure if it helped, but the saw runs well. It definitely needs a lower exhaust port and higher compression.

Below, one side of the lowers setup, about to fill the other, but before smoothing and clearancing for the piston.

View attachment 565

No time spent purtying up the exhaust port, just hogged it out a lot.

View attachment 567

View attachment 568

In the video I was testing the stock muffler on it because the one I modified to exit out the front felt like it may have lost some low end torque, but gained a little high end torque. Even though the ms250 seems to have a lot of cooling surface area compared to other saw engines, it starts out quite sporty when cool, but after 5min or so of non stop firewood cutting, it seems to slow down a lot.

First cuts, not broken in yet, still tuning during that session. I attribute the low end torque to the raised and widened intake. I might leave the intake lower on my second kit. Cedar, then Hickory.

View attachment 566

Nutball

Active member

2511t I ported. No funny fuel, just gasoline with 40:1 oil.

View attachment 2511t 20in Super Modified.mp4

View attachment 2511t 20in Super Modified.mp4

Mastermind

Active member

2511t I ported. No funny fuel, just gasoline with 40:1 oil.

View attachment 610

That is WOW. JUST WOW.

Good work Remington.

Yep. Thats a snotty lil dude. Super flow ported n stuff.That is WOW. JUST WOW.

Good work Remington.

Buxton_Work_Saws

Member

Little 555 action

Sent from my Pixel 4a using Tapatalk

Sent from my Pixel 4a using Tapatalk

Butter

Ported 661, 18" setup with a 10 tooth 375

Nutball

Active member

Echo 303t 14" in 14" dryish Ash. I'm not a fan of these Oregon chains. Stock cut that log in 43.5 seconds

View attachment Ported 303t short.mp4

Ported cut in 22 seconds

View attachment Ported 303t short.mp4

Ported cut in 22 seconds

BigSachsDolmar

Member

Nutball

Active member

Torquey ported 490 in Ash. Stock cut that log in about 25 seconds.

View attachment Ported 490 short.mp4

View attachment Ported 490 short.mp4

Iroczu

Member

Wonder how the balance is with that bar on there?! Lol all jokes aside that thing rips2511t I ported. No funny fuel, just gasoline with 40:1 oil.

View attachment 610

Iroczu

Member

As the saying goes, the more you know the less you actually know when it comes to this stroke porting game. I did a really wonky thing on the intake port on the 026 and it for what ever reason made a night and day differenceWhen I had a few hundred saws under my belt, I thought I had a lot of this stuff figured out. I would do a lot of build threads, and post a lot of videos. I shared my knowledge freely. I wouldn't necessarily say the information I was sharing was all wrong, but it wasn't all as accurate as it could have been either. The thing was that as I learned more, I realized that some of the stuff I thought I knew wasn't as true as I thought it was. In other words, the more I learned, the less sure I was about sharing. The problem is, there are so many different types of saw engine, that there is no certain recipe that applies to them all. For instance, the Husqvarna 5 series is a strato engine with really long transfer tunnels. It uses a very short blowdown time. The Stihl 201, 261, and 362 are also stratified but have short tunnels, and use a longer blowdown time. Rather than just grab a set of numbers from someone else's build thread, we should all be trying to figure out why these engine designers used the timing numbers that they did. Another example, using non-stratifed engines: The Dolmar 7900. Really tight transfer tunnels, and pretty small ports for an 80cc saw. This saw is designed with a long blowdown time. About 26° or so. The 7900 is a quad port design. The Stihl 046 has a two port design, wide open transfer area, and employs a very short blowdown time of about 14 - 16 degrees. I encourage everyone to study these different designs and try to figure out why they use such widely varied port timing numbers rather than playing follow the leader on their builds.

Fabz

Active member

Husqvarna 572xp Hotwoods Torque port and a STIHL 462c Hotwoods port with K/N filter and machined intake. Looks like the STIHL (72.2cc) took the Husqvarna’s (70.7cc) lunch money. With some intake work I can make the Husqvarna quicker but I’m loathe to mess with it as it’s a damn good stock filter setup. The stock STIHL filter situation on the other hand isn’t so great ...

Attachments

Last edited:

Nutball

Active member

572 seemed quieter and didn't appear to get leaned on as hard. Maybe that's why it was a little slower? Looks like a similar muffler mod on the 572, so I don't know why it is quieter. Quick chain though on both.