Hi Bob – Stump Shot, Thanks for your patience,

Sorry for the slow reply but I was trouble shooting one of our water transfer pumps….Fixed.

Well, I’m considering hooking up the saw to the tractor and dragging it around a paddock….or digging a hole, bury it and end the frustration.

Bob, Took onboard your idea of the one commonality, the plug, Pulled the definite ok one from the 310…no spark.

See Attached:

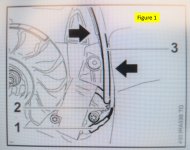

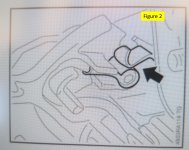

The ground / contact wire is only grounded at the coil, as in the Figure 1 diagram attached, wire 2. Wire 1 is the short circuit (kill) wire, the other end of the kill wire goes to the kill arrangement in the Figure 2 diagram attached and operates via the ground / contact wire spring arrangement making contact with the kill wire terminal when the run lever is in the off position. The wiring arrangement is installed correctly, and I have continuity on both wires.

I did wonder (not being an expert and clutching at straws) if the JB Weld Red Hi-Temp RTV Gasket Maker And Sealant I used between the crank case and cylinder was impeding continuity (I know but clutching) as the coil is located on the crank case but I’ve checked continuity between the 2 components and it’s good.

As I mentioned before….3 coils with questionable readings??? So, I’m now going to remove the coil from the 310 and see what readings we produce.

If inconclusive, I may consider hurling myself off the roof and rely on reincarnation

Cheers……Stuart