Anyone interested in a chainsaw Dyno?

Built mine last year, and have most all the bugs worked out now. Almost 1000 runs on the current setup.

If you all want to see some build/progress pics along the way let me know and I will dig them up.

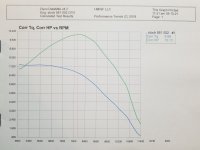

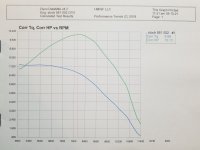

Here is a printout from the dyno system. I use a waterbrake, with shafting/fatherless chain to mount the powerheads on.

Runs are done just like cutting wood. High/max rpm then I start applying the load and bring them down to 5000 rpm over a 9-12 second time.

Built mine last year, and have most all the bugs worked out now. Almost 1000 runs on the current setup.

If you all want to see some build/progress pics along the way let me know and I will dig them up.

Here is a printout from the dyno system. I use a waterbrake, with shafting/fatherless chain to mount the powerheads on.

Runs are done just like cutting wood. High/max rpm then I start applying the load and bring them down to 5000 rpm over a 9-12 second time.