You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Chainsaw Dyno?

- Thread starter Red97

- Start date

Cole has one of each, but they’ve been dickered with. Probably slower than stock

Cole has everything

Moparmyway

Member

What are you calling "the barrel"?I know I’ve been able to get 15-18% quicker cut times on the 462c with the stock barrel and around 27-33% with the barrel flow-ported. Not sure what the hp is but bmep says about 7.5-7.8

The cylinder ??

Fabz

Active member

Barrel, cylinder, jug etc ...

Fabz

Active member

Fabz

Active member

I tested her (064) this morning in a few different species , red oak and hard maple. With my prepared chain (sharpened , rakers , gullet etc) she was around 11,000 in the timber with self-feeding and about 10,850 dogged in with light pull. She 4-strokes at 13,200 which is a nice safe spot ... That’s with a 20” b/c and a very , very sharp chain. When I get bigger wood I’ll test with a 28”

Last edited:

Nutball

Active member

Fabz

Active member

What rpm does your TreeMonkey 064 cut in the wood , self feeding and then dogged-in (with a sharp chain of course)? I can’t see all the results , the photo is chopped off below 10000rpm. Do you have a video of it cutting ?

Nutball

Active member

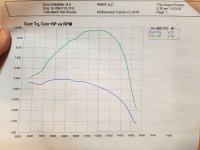

On the graph, I think it should be doing all it's cutting in the 10,600-12,600 range ideally, and at over 4 ftlbs of torque it should powerfully sport a 28" bar through hardwood at that RPM.

But here's the proof: bouncing between 8400 & 9500, running peak torque in that range (4.9-5ftlb) 8-9hp, in 30" oak, 9 tooth rim

But here's the proof: bouncing between 8400 & 9500, running peak torque in that range (4.9-5ftlb) 8-9hp, in 30" oak, 9 tooth rim

Nutball

Active member

@Red97 Is there a good way of getting the ideal tune for a dyno run by tuning it under some load on the dyno? Personally I wouldn't want any of my saws every revving over 14k at any time unless given permission because crazy high rpm puts a lot of stress on an engine, having to accelerate the piston in different directions so fast. Just something to think about for customer saw life, and even personal safety in case a flywheel had some defect. I didn't know it would rev up near 16k, and I read someone had a race saw flywheel blow around 17k. Then there's potential harmonic distortions and such.

@Red97 Is there a good way of getting the ideal tune for a dyno run by tuning it under some load on the dyno? Personally I wouldn't want any of my saws every revving over 14k at any time unless given permission because crazy high rpm puts a lot of stress on an engine, having to accelerate the piston in different directions so fast. Just something to think about for customer saw life, and even personal safety in case a flywheel had some defect. I didn't know it would rev up near 16k, and I read someone had a race saw flywheel blow around 17k. Then there's potential harmonic distortions and such.

In the case if your 064 it kept gaining as the rpm went up.

It was pig rich at 13k and by the time it finally cleaned up under load power was on the down slope. 14k is pretty common on 066/064 chassis. That saw wasn't at the high rpm for all but a split second before the load starts pulling it down.

Long bar full load like in the video it is going to be hard for a saw to ever get up close to peak hp. It will say down around peak tq.

The peak hp will be small wood/limbing area. Or racing type situations.

Fabz

Active member

Roosevelt, that the saw will rev to 16000rpm is meaningless ... What rpm it cuts at dogged-in under load is what really matters. This is a function of torque and we extrapolate hp from torque. The 2 saws I have from Hotsaws101 will pull 11,500 in the timber with a prepared chain

Last edited:

Here is the full 064 graph.

Which verifies peak tq in the 8500-9500 range. Right were it was full load with a big bar and sprocket.

Fastest cutting speed has more to do with chain tune.

This saw is more "high strung " than most being peak tq is up around the 9k mark vs the 5-7k of most other saws. That is part of the reason it wants to spin. It is making its power hp and tq higher than most.

Should send one in for some pulls. See if you need to drop rakers a bit moreRoosevelt, that the saw will rev to 16000rpm is meaningless ... What rpm it cuts at dogged-in under load is what really matters. This is a function of torque and we extrapolate hp from torque. The 2 saws I have from Hotsaws101 will pull 11,500 in the timber with a prepared chain

Fabz

Active member

I agree with this statement. With a poorly prepared chain We aren’t doing anything but burning up the saw. In fact a stocker with a Razer sharp chain can and will outperform the same version ported saw with a so-so chain. I Shoot for gobs of torque down low in my builds as this seems to translate into a better performing chainsaw (with a properly prepared chain of course) in the wood. We have to remember the final link is the chain and our “gearing” options are limited to 7,8,9 pin drive sprockets. If I was building a kart engine raced on a track with long straightaways I’d build for mid-high end, tight twisty track low to mid but STIHL wind out on topView attachment 912

Here is the full 064 graph.

Which verifies peak tq in the 8500-9500 range. Right were it was full load with a big bar and sprocket.

Fastest cutting speed has more to do with chain tune.

This saw is more "high strung " than most being peak tq is up around the 9k mark vs the 5-7k of most other saws. That is part of the reason it wants to spin. It is making its power hp and tq higher than most.

Fabz

Active member

I’m running .026-.031 on the rakers, seems to pull nice chips. I’m not an advocate of dropping them excessively low, I’ve found thru experience it’s counterproductive when cutting hardwood - beats the piss outta the saw and the sawyer. Right now I’m very busy with saw work so sending that one in isn’t in the cards. I can send in the Hotsaws101 241c insane-0 version if you can run it, running 7pin 3/8 picco so not sure if you can accommodate thatShould send one in for some pulls. See if you need to drop rakers a bit more

Last edited:

Robin Wood

Member

- Local time

- 9:45 AM

- Joined

- Sep 3, 2021

- Reaction score

- 46

Bingo!I agree with this statement. With a poorly prepared chain We aren’t doing anything but burning up the saw. In fact a stocker with a Razer sharp chain can and will outperform the same version ported saw with a so-so chain. I Shoot for gobs of torque down low in my builds as this seems to translate into a better performing chainsaw (with a properly prepared chain of course) in the wood. We have to remember the final link is the chain and our “gearing” options are limited to 7,8,9 pin drive sprockets. If I was building a kart engine raced on a track with long straightaways I’d build for mid-high end, tight twisty track low to mid but STIHL wind out on top

Chain is the final piece of the puzzle, it has to suit the power heads hp/torque delivery. If its a high torque motor you can drop rakers a little and bring it to the rpm range it works best. If its a high rpm saw, go easy on the rakers and let it spin more and self feed. Usually works best with more hook on cutter and taller rakers