This is my first real Stihl build, I've done a couple of Stihl clones and I thought it was time to try a real one out. I got this off ebay and I'm sure I paid to much, like is often the case when you buy your saws there. This is what I'm starting with, pics from ebay.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

026 build

- Thread starter Ronie

- Start date

A week or so ago I did a muffler mod for it because I was board and didn't feel like cleaning the saw up, the part I hate most. I posted this in the muffler mod thread but I'll put it here also to keep everything together.

Attachments

As it stand now, I've taken it a part and cleaned everything up and vacuum tested it, bad seal killed it. I removed the scored cylinder and cleaned it up, it had a lot of transfer in it but cleaned up well enough to use. It came with a 44mm Mahle cylinder and I also have a nice 44mm Stihl cylinder, I'm not sure which one I'm going to use but I'm leaning towards the Stihl one. Pics are after cleaning except the piston.

Attachments

Last edited:

Nutball

Active member

Not sure on the timing numbers yet but probably something like EX 96 , TR 24-26 opening the EX side first and IN 78.Do you have a goal for timing numbers?

I cut out some plastic in my air filter (the part that divides the upper from the lower part), it's probably some sort of spit back guard. I also replaced the flocking with nylon mesh.

View attachment 749 View attachment 750

Filter looks great, I might go with a velocity stack but if I use the mesh one I'll open it up and see what I can do about the divider.

Last edited:

Nutball

Active member

If you plan on test running the aftermarket cylinder, start by making the exhaust port as low as you feel safe doing, then run it, then run it again @ 96. Stock they are only good for 8" wood in my opinion, and need more torque. I haven't run one ported with that high of exhaust, so I'm not 100% sure what the outcome will be. I think mine is around 99-102, and goes through 16" wood well. I wish I would have made it lower, but that's a lot of machining already.

Last edited:

I figured I'd start with just removing the little squish band, that should put it around 96 and see how it does.If you plan on test running the aftermarket cylinder, start by making the exhaust port as low as you feel safe doing, then run it, then run it again @ 96. Stock they are only good for 8" wood in my opinion, and need more torque. I haven't run one ported with that high of exhaust, so I'm not 100% sure what the outcome will be. I think mine is around 99-102, and goes through 16" wood well.

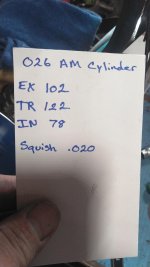

The $21 AM cylinder showed up today, the casting and ports look good, upper transfers are angled toward the intake like they should. I'll try the numbers above out on this one first.

Attachments

Nutball

Active member

Looks good.

Iroczu

Member

This is my current numbers for my 026, 24 inch bar 3/8 full comp was running skip before and no issues with it neither , I also tested with a 18 inch and .325 chain and it was Rowdy, these saws like their rpm I've found and it doesn't usually see much more then 20 inch soft wood anything bigger I'll grab the husky 162se or the ported 038 mag

Ex 98 atdc

Transfers 120 atdc

Intake 74 btdc

24 deg bd

Ex 98 atdc

Transfers 120 atdc

Intake 74 btdc

24 deg bd

Iroczu

Member

Here's the dumb tests of tests

tacotodd

Member

That reminds me of the test that I put my 372xt through with my generous MM on. It did sorta ok with full comp but was borderline right with full skip. For now mine will wear the 28”er, BUT SOMEDAY…Here's the dumb tests of tests

Iroczu

Member

I wouldn't ever run the 026 with a 32, video was for curiosity purposes, which I in think it would pull that chain, oiler won't keep up to a bar that size, av mounts maxed out it is definitely a if you want to destroy your saw go for it lol have some interchangeability things to try out now for the oiler and some stiffer av mounts. OP depends what bar you are wanting to run I can keep you updated on how thus swap goes in coming days when I can get to itThat reminds me of the test that I put my 372xt through with my generous MM on. It did sorta ok with full comp but was borderline right with full skip. For now mine will wear the 28”er, BUT SOMEDAY…

Looks good, this one will be getting a .325 16" bar.Here's the dumb tests of tests

I cut a little more out of the squish band and finished the ports up, as soon as my seals come in I'll get it together and see how it runs.

Attachments

Iroczu

Member

Is your squish with sealant or a base gasket? See how it runs, I'm using stock domed piston and a tad tighter squish, but the lower transfers I ran mine almost to the base of the cylinder and found bigger gains by opening them up a bit longer in mine. This ported 026 is getting shipped down south and I just picked up another stock one to port going to try some other little things to it this time aroundI cut a little more out of the squish band and finished the ports up, as soon as my seals come in I'll get it together and see how it runs.

Squish is without a base gasket. I'm not sure yet what I'm going to do with the lowers, I might take some JB Weld and fill in the lip to smooth the flow or drop them down a little and smooth it out.Is your squish with sealant or a base gasket? See how it runs, I'm using stock domed piston and a tad tighter squish, but the lower transfers I ran mine almost to the base of the cylinder and found bigger gains by opening them up a bit longer in mine. This ported 026 is getting shipped down south and I just picked up another stock one to port going to try some other little things to it this time around